Our Mission

Satellite structures made of aluminum have long been popular in space applications due to their properties. However, high production costs and increasing demand pose a major challenge. Manufacturing each structure through CNC milling and a manual assembly of all components requires a lot of time, resources and materials, which drives up the cost of each unit. With the advent of mega-constellations and a growing demand for small satellites, the traditional one-off manufacturing approach is no longer viable. Innovative approaches and production techniques are needed to provide the required number of structures at a reasonable cost.

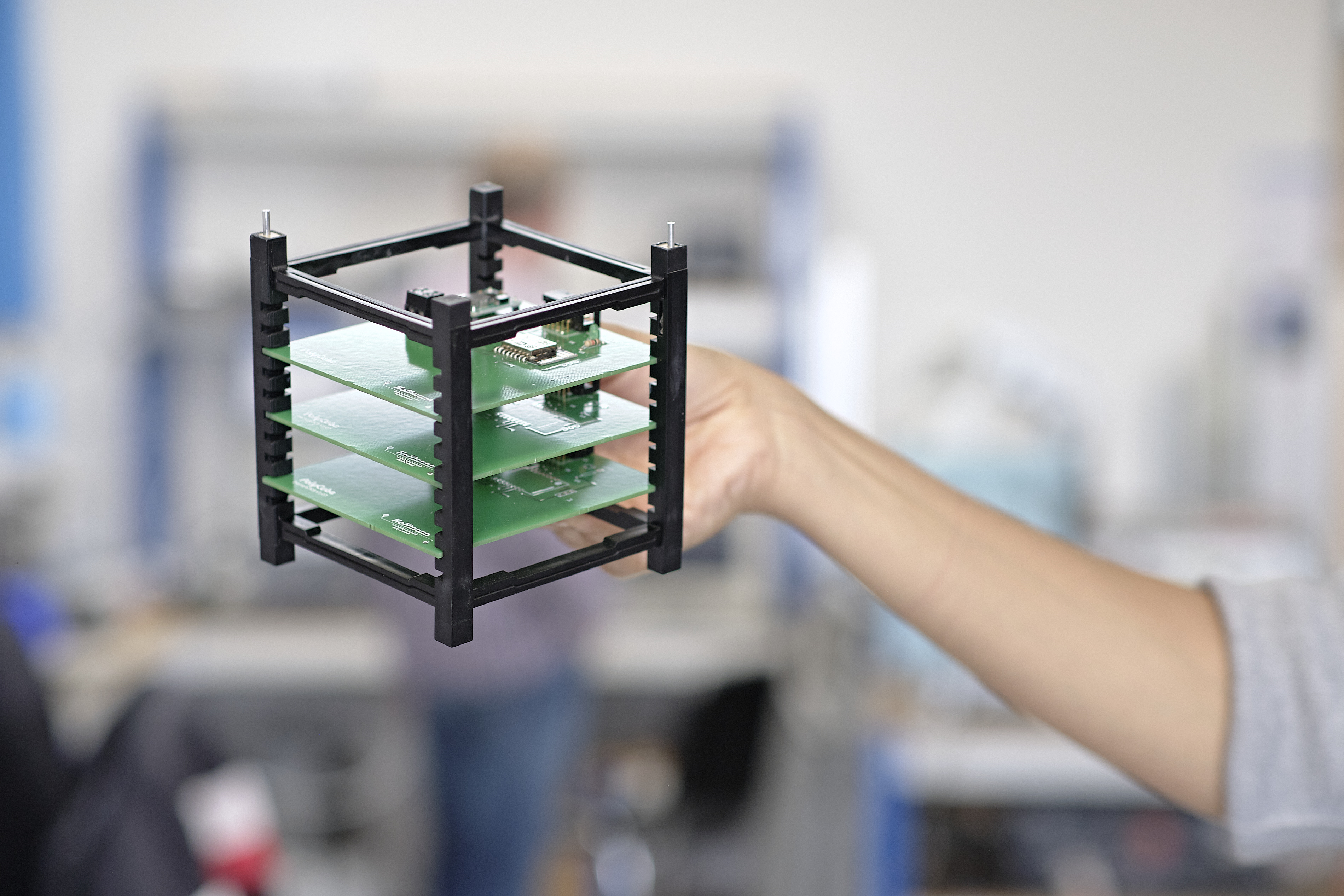

LambSpace aims to revolutionize the small satellite industry, firstly by producing high-performance polymer structures from PEEK using injection molding. This approach shortens production time compared to aluminum structures, lowers costs, minimizes resource use and offers advantages such as lower mass, better corrosion resistance and a lower carbon footprint. On the other hand, LambSpace aims to develop and manufacture new innovative small actuators based on shape memory alloys. This technology is particularly well suited for space applications due to its light weight and robustness. Shape memory actuators can be used for various locking and unlocking tasks, such as unlocking antenna modules.

We are committed to delivering technically superior and cost-effective satellite solutions while reducing environmental impact. Our goal is to become a leader in the mass production of satellite systems to meet the growing market demand for mega constellations.