CubeSats

In the past, satellites were colossal systems, weighing several tons and demanding substantial budgets, extensive time, and high levels of expertise for development. Today small satellites have facilitated easier access to space over the last decade. CubeSat standard represents more than 90% of all launched nanosatellites.

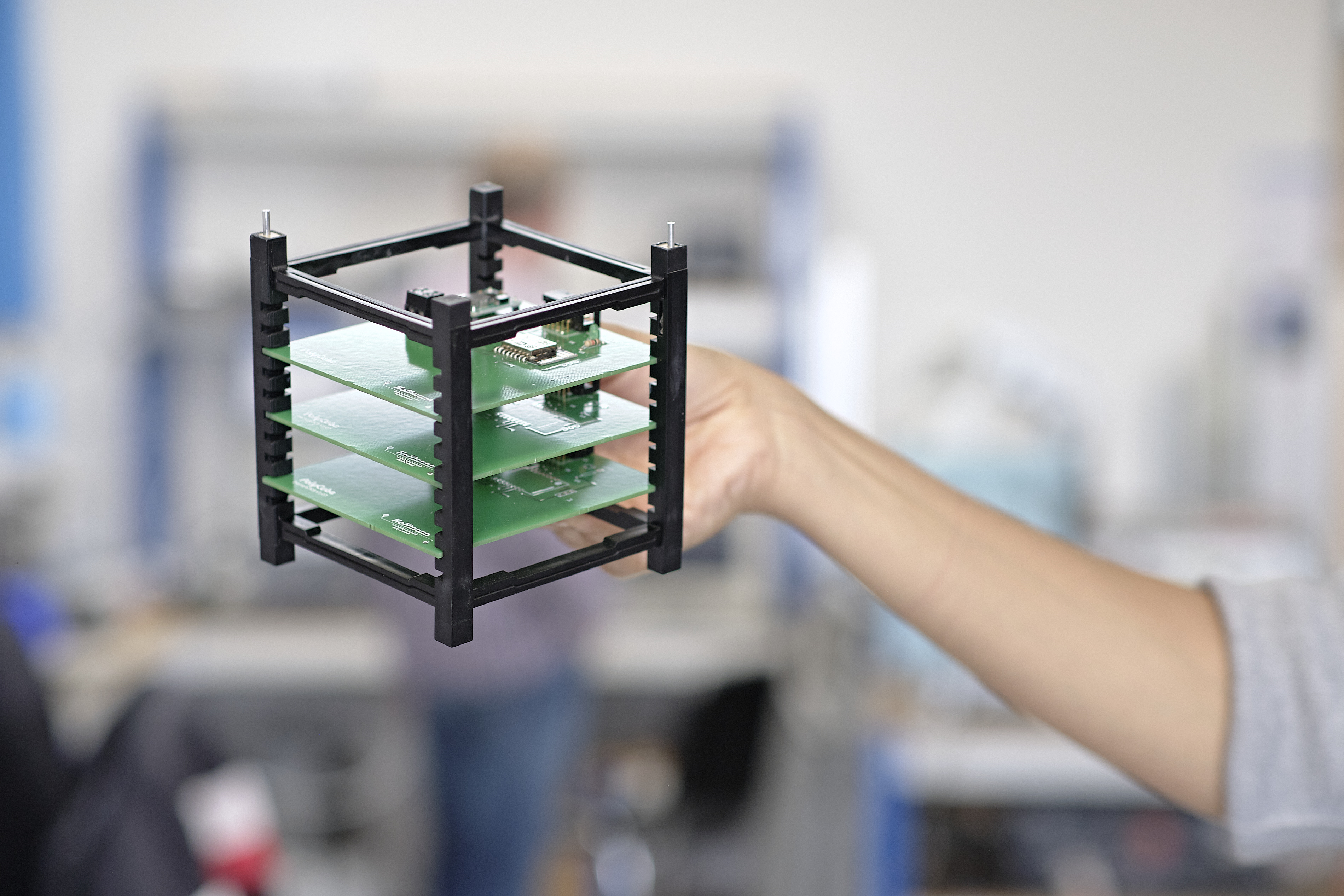

A CubeSat, short for Cube Satellite, is a satellite characterized by a cubic shape. The fundamental configuration of a CubeSat comprises a 10-centimeter (4-inch) cube (1U), weighing less than 1.33 kilograms (2.93 lbs.). However, there is room for flexibility in design. CubeSats can be adapted to incorporate two, three, six, or even twenty four units (24U) for more intricate missions. These miniature satellites designed for space research and exploration purposes, especially favored for their standardized size and the utilization of commercial off-the-shelf (COTS) components.

More environmentally friendly for space missions!

It’s essential to consider the entire life cycle, including extraction, production, use, and disposal, to make a comprehensive assessment of the environmental impact of a material in a specific application.

Here are some important points:

- Lower weight: In aerospace applications, where weight is crucial, every gram of weight saved results in fuel savings, a factor of utmost significance for your mission costs.

- Lower production Energy: The production of aluminum requires more energy than the production of plastics. The extraction and processing of aluminum from bauxite ore involve significant energy inputs, while this value diminishes, particularly with recycled plastics.

- Zero waste: Defective products or materials wasted during the process are recycled and reused, undergoing shredding and melting for a new purpose, while this is not as straightforward with leftover aluminum chips due to the milling process.

- Better End-of-Life Disposal: Plastics can burn more quickly during re-entry into the Earth’s atmosphere and therefore pollute our atmosphere less than metals. Their residues (metal oxides) remain in the atmosphere, although the negative effects of this are still the subject of current research.

Benefit from the advantages of our technology!

As we value the comfort of our customers, we go beyond merely embracing benefits like lightweight construction, environmental friendliness, and cost reduction. Within our CubeSat structure, we’ve incorporated specific technical advantages to streamline the assembly of components for our customers. Moreover, our CubeSat structure provides the following benefits:

- The mass production of CubeSat structures enables customers to benefit from swift delivery times and eliminates delays for spare parts and subsequent shipments.

- The stability achieved through injection molding renders secondary structures unnecessary.

- Customers require no mounting process or assembly effort, as our structure is created in a single unit.

- We seamlessly integrate mechanisms, including kill switches and the deployment of solar panels or antennas, directly into our structure.

- Achieve plug-and-play convenience for any PCB board at any time, thanks to the built-in slide-in rails within our structure.